Postforming High Pressure Laminate

BODA specializes in the production of postforming high pressure laminate, which is known as PF HPL. They possesses characteristics of high density, design, superior physical performance, safety and environmental protection, rapid processing, construction, installation and use. It is widely used in various decorative surfaces, such as furniture, cabinets, interior doors, partitions, countertops, decorative ceilings, walls, pillars, and more. Our PF HPL has covered most of Asian and North American market like Singapore, Malaysia, Thailand, Vietnam, Canada, etc.

Send Inquiry

Product Description

1. Product Details of The Post forming High Pressure Laminate

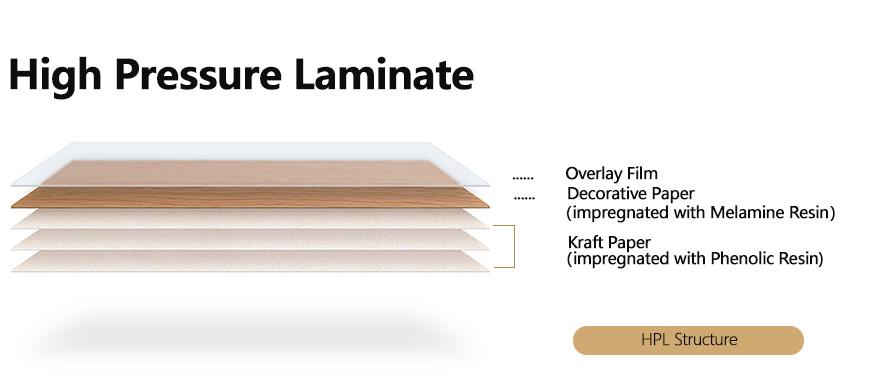

BODA Post forming high pressure laminate is made of overlay film, melamine decorative paper and phenolic resin kraft paper.

BODA PF HPL has the advantages like: Bold and realistic designs, rich in colors, including, but not limited to solid colors, woodgrains, stones, metals, patterns, and more. Enhanced haptic solutions with a variety of surface textures. Durable wear-resistant surface. Postforming high pressure laminate which is suitable to create rounded edges for worktops and other surfaces.

2. Product Introduction of The Post forming High Pressure Laminate

Post forming high pressure laminate (PFHPL) also known as a refractory board, is a high-tempered laminate board of the thermosetting resin impregnated paper. PFHPL is a fire-resistant, decorative surface, building material.

Our PFHPL possesses characteristics of high density, design, superior physical performance, safety and environmental protection, rapid processing, construction, installation and use. It is widely used in various decorative surfaces, such as furniture, cabinets, interior doors, partitions, countertops, decorative ceilings, walls, pillars, and more. Our PF HPL has covered most of Asian and North American market like Singapore, Malaysia, Thailand, Vietnam, Canada, etc.

In the development process, in addition to strict implementation of quality standards and environmental standards, our company also strictly controls the supple of their materials. For domestic materials we source from companies who share our environmental protection values, including, but not limited to KINGDECO and Qifeng. Additionally, when it comes to the raw materials of our product we chose from well-known brands from Europe, the United States, and Japan, including Kapstone, Kotkamills, Munksjo, Schattdecor, Surteco, Lamigraf, Interprint, Toppan, and more. The production of environmentally friendly products and the commitment to environmental protection are the values that Boda as a company has always pursued.

3. Product Parameter (Specification) of The Post forming High Pressure Laminate

Size Specification:

1220x2440mm(4’x8’),

1220x3050mm(4’x10’),

1525x3050mm(5’x10’),

1525x3660mm(5’x12’)

Vertical Grade Thickness: from 0.5mm to 0.6mm

4. Product Feature And Application of The Post forming High Pressure Laminate

BODA Post forming high pressure laminate (PFHPL) products are rich in surface colors, textures, and special physical properties. Characteristics include resistance to wear, scratch, impact, and high temperature. PFHPL is also easy to clean. PFHPL is generally used on a single side and should to be attached to a substrate for proper use.

PF HPL widely used in various interior decorative surfaces, including furniture, cabinets, interior doors, partitions, countertops, decorative ceilings, wall surfaces, pillars and more.

5. Product Qualification of The Post forming High Pressure Laminate

BODA Post forming high pressure laminate has gradually passed EN438, NEMA, CE, FSC, GREENGUARD and has improved the quality of inspection and monitoring throughout the entire production process. The system ensures the quality and stability of its products, simultaneously, the technical follow-up and technological innovation are continuously improved, as well as the product specifications and collections.

6. Deliver, Shipping And Serving of The Post forming High Pressure Laminate

Lead Time: 15-20 days

Shipping term is flexible: EXW, FOB, CIF, etc.

Payment Term: T/T

7. FAQ

Q: Why is post forming laminate priced higher than general purpose laminate?

A: Post forming grade laminate costs more to produce because it requires premium papers and resin treatments. Quality control must be tighter to assure a well-manufactured product that will perform properly.

Q: What is the blister point of post forming laminate?

A: Blister points for post forming and general purpose grade laminate is in the range of 400 degrees Fahrenheit(204℃). The time at any given temperature is a big factor. Post forming grade laminates should never blister in less than 40 seconds if temperature is quickly increased to 325 degrees Fahrenheit(162℃) in 25 + 5 seconds. This margin assures good forming and good blister resistance. As an example, a hot pot containing oil heated to 356 degrees Fahrenheit(162℃) will not blister laminate as it cools, but if this temperature is maintained, damage may result.

Q: Do all BODA laminate products post form? Why do some colors post form more easily?

A: No, only some products are manufactured to post form with the aid of heat. The laminates finish, color, and/or pattern will affect the heat transfer rate throughout the laminates thickness. As an example, white laminates will reflect heat and therefore will require more heat to transfer 325°F(162℃)in 25 + 5 seconds throughout the laminate thickness. Dark laminates will absorb heat and therefore will require less heat to transfer 325°F(162℃) in 25 + 5 seconds throughout the laminate thickness.

Q: How to clean high pressure decorative laminate sheets?

A: There are three steps to daily cleaning.

1. Use a clean, damp, non-abrasive cotton cloth and a mild liquid or household cleaner. Use rotary motion to clean dirty areas.

2. Next, use a clean, non-abrasive cotton cloth and rinse with water. Be careful not to flood the laminate, especially near the joints, as water can seep in and cause the substrate to expand.

3. Dry surfaces with a soft, clean, non-fraying cotton cloth.